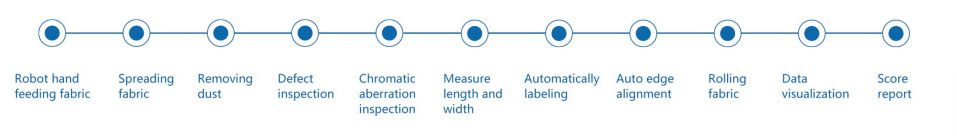

The first Artificial intelligence Fabric lnspection Machine with self-learning ability , based on self-developed Al algorithm

Intelligent fabric inspection machine

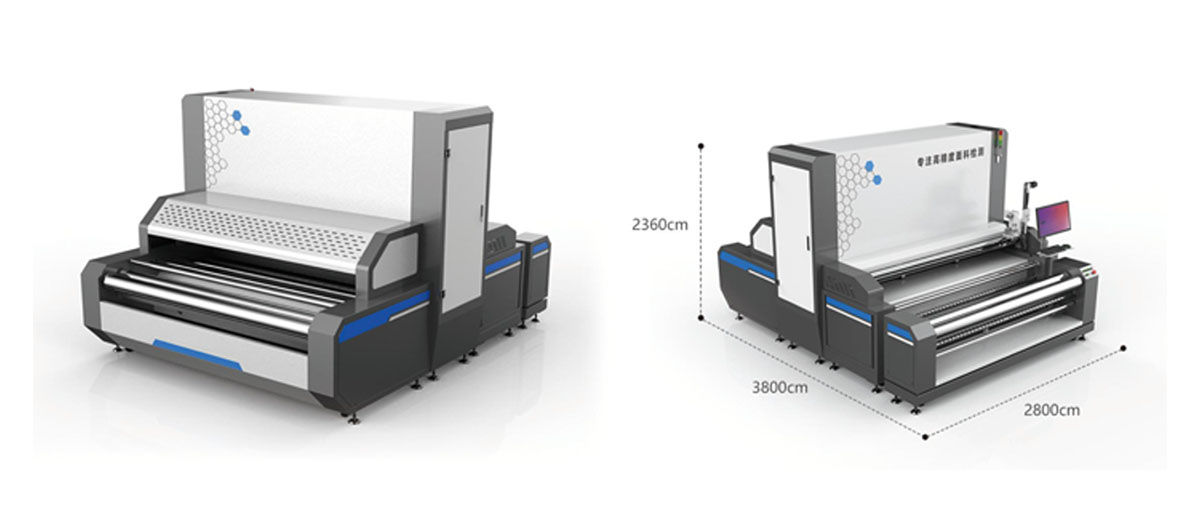

Model: YL-01 Garment factory model (Rolling to Rolling)

Garment factory model YL-02 (Rolling to Relaxing)

Dyeing factory model YL-03 (Relaxing to Rolling)

The first Artificial intelligence Fabric lnspection Machine with self-learning ability , based on self-developed Al algorithm

Suitable for knit、woven monochrome fabric

DETECTABLE DEFECT

Hole、Stain、Broken Yarn、Crease mark,Knot、Coarse Yarn、Dropping stitch、 Broken stitch、 flying. Shadow、 Color difference etc.

Chromatic aberration:Color difference in left & right edge and middle (lateral chromatic aberra-tion) , color difference in beginning and middle and the end, color difference in different roll fabric from the same dyeing tank.

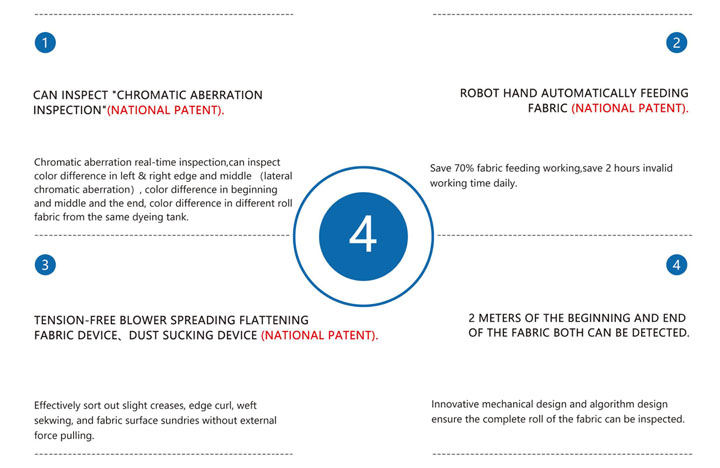

4 NEW ADVANTAGES

CORE ALGORITHM TECHNOLOGY

Based on I50/MPEG CDVA International standard tech-nology which was led by our team in 2015 ,we successfully developed a high-precision detection algorithm for fabric defects.

With Al algotithm seif-learning technology and the accumu-lation of data, our machine can think independently and become more and more intelligent in the future.

We have adopted more difficult and potential dection methods .Therefore,We have better detection effect for detection of chromatic aberration and some defects with depth characteristics.Such as creasers.

Our technology can extract and analyze image features at the level of 10 billion in miliseconds.

BENEFIT OF INTELLIGENT FABRIC INSPECTION

1.HIGH EFFICIENCY, REDUCE LABOR

Replace 2-5 traditional fabric inspection workers, saving millions of cost for the company every year.

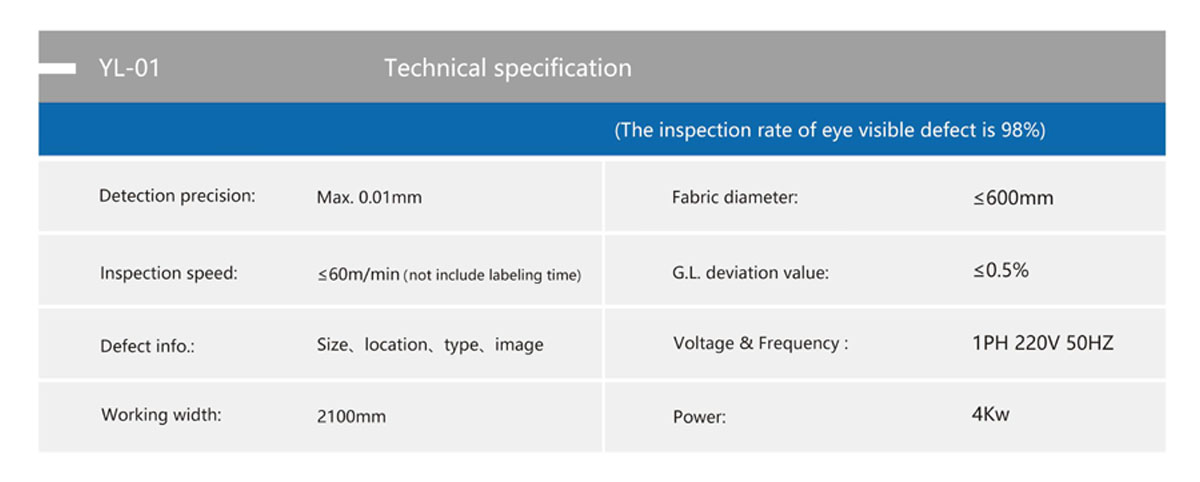

The average speed of manual fabric inspection:15-20m/min; the average speed of intelligent fabric inspection:60m/min.

2.HIGH RECOGNITION RATE, REDUCE COMPENSATION

Cmplete fabric can be inspected, the inspection rate is stable, and itis higher than manual , which can reduce the customer compensation problems caused by random inspection and inaccurate inspection.

The average manual inspection rate: 70%, the highest recognition accuracy: 0.1mm;the average inspection rate of the intelligent fabric inspection machine: more than 90%, the highest recognition accuracy: 0.01mm.

3.IMPROVE THE STABILITY OF PRODUCTION CAPACITY

Uninterrupted operation in 24 hours, reducing the dependence on people, preventing production capacity fluctuations caused by social epidemics, staff leave, and departures.

4.INFORMATIZATION AND DIGITIZATION

Open APl interface ,connect with ERP, MES and other systems ,can connect with automatic equipment such as automatic cutting machines and fabric spreader as well to form a textile intelligent production line to create atextile intelligent factory.

OTHER FEATURES

1.Use multiple high-pixel cameras are used to automatically inspect the fabric defects, ensure the continuity and accuracy of the inspection.

2.Self-adjustment of brightness: No need to manually enter the color and thickness of the fabric.

3.The briahtness wil be automatical adiusted according to the actual imaging effect of the fabric, and the problem of inspection rate decline due to aging of the light source is avoided.

4.Automatic alarm when recognizing defects, optional "automatic / semi-automatic" inspection mode, the semi-automatic mode needs manual review ,to meet the customized defect inspection demand.

5.Professional fabric inspection report: after inspection, it will automatically score according to the "American Standard Four-point System", output a professional fabric inspection report , which can also be customized according to customers requestment.

6.Information cloud storage and big data analysis: defect and fabric information report cloud storage, invoke at any time, can check the fabric inspection info at real-time.

7.The whole machine adopts original imported control electrical appliances: Japan Panasonic PLC Japan Mitsubishi inverter, etc.

Contact: Amily

Phone: +86-18614084502

E-mail: 3640978@qq.com

Add: Ho. 1-2921 Yongledian Town Enterprise Service Center, Tongzhou Beijing